T-shirt printing is a lucrative business that has been booming recently. The custom t-shirt printing in 2022 is valued at $4.3 billion which is projected to reach $7.57 billion by 2030. This indication shows how the t-shirt printing business is skyrocketing. You don’t need a big office space before you can start your t-shirt printing journey but you can start in your garage, porch, or any small space in your house.

A lot of questions are asked about the tools and equipment that are used for printing t-shirts. I did intensive research and here are the common responses I found across. Heat press machine/hair dryer / electric iron, mesh, squeegee, Teflon, ink.

Below is a detailed explanation of all the equipment needed for t-shirt printing.

1. Heat Press Machine

The heat press machine is the most important equipment needed for t-shirt printing. The purpose of the heat press machine is to provide a direct source of heat for the printing which ensures that the ink adheres to the fabric. In place of the heat press machine, an electric iron, and handheld hair dryer can be used for t-shirt printing.

The disadvantage of using this equipment (dryer and electric iron) is that it is not recommended if you are working on bulk orders because it wastes time. Iron can’t also provide the required amount of pressure needed to heat the t-shirts. The heat press machine makes it easy for users to regulate the temperature of the machine, allowing users to have an equal and even heat transfer.

2. Plain T-Shirts.

Ralawise, Gildan, and Polo are some common brands from which you can source your plain t-shirts. These brands offer quality t-shirts that you can use for your printing. They also provide and distribute hoodies, sweatshirts, and singlets that you can use for your printing. These plain t-shirts brands offer various variations in texture, color, and weight. Cotton-type t-shirts and polyester are the common brands that you can choose from for your t-shirt printing.

3. Squeegee

A squeegee is a metal, plastic, or wooden tool used for pushing ink through the screen to the t-shirt. It comes in various sizes making it easy for you to accustom yourself to the size and type that works best. In choosing the type or size, you should consider how easily your fingers can grip the squeegee, the weight of the squeegee and its accessibility on the market, and the ability to clean it easily after using it.

4. Teflon Sheets

Teflon is incredible for shielding the design and the heat press by acting as a barrier between the heating surface and the fabric. The Teflon is a major component in t-shirt printing, teflon sheets prevent inks on fabric from sticking to the surface of the heat press.

5. Ink.

The inks come in various colors and thicknesses. The most common ink used for t-shirt printing is plastisol because of its vivid and shiny surface after printing and its ability to last timeless after it has been printed onto a shirt. The plastisol is manufactured from PVC particles that are suspended in a plasticizer. Other forms of inks are water-based inks, discharge inks DTG ink.

6. Mesh

In t-shirt printing, mesh is one of the tools we use to accomplish our t-shirt printing goals. Mesh is made from polyester material or silk material. It is a screen that acts between the t-shirt and the ink. It has visible holes that allow the paint to pass through for the design to appear on the shirt.

Every mesh is measured in mesh count. Mesh count is the number of holes that are in the screen. When considering the mesh type, you should know that a higher mesh count does not allow more ink to pass through the mesh on the fabric and vice versa.

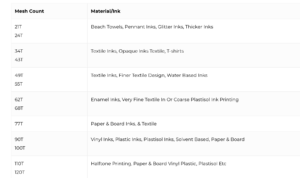

The table below guides us more in understanding the mesh counts for various printing materials.

This table is a screenshot from hickmandesign.co.uk.